Anybody who follows progress on the Facebook page will be aware that the grey elephant that is not in this blog is the mammoth January 2025 riveting session (awful metaphor but could not resist it). Putting the big bag of dome head rivets to one side is the selection of non-standard ones, with different length and head combinations.

No small amount of time has been spent debating the best way to carry out the job. On the loco or off the loco? With a squeezer or with guns? The best way to hold up. In the end we opted for two guns, with just a initial bit of hammering on the holding up side. All the work was done off-loco, with sub-assemblies being clamped to stands and flipped to keep the work zone at a convenient height.

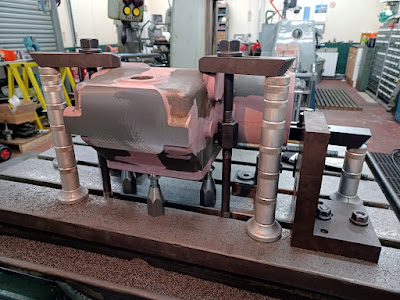

Side one set up and ready to go.

Heat, camera. Action!

Despite appearances, this is not a spectator sport, Rimmer (in brown) is tending the forge & delivers the rivet, Tim (beanie hat) taps the rivet home into the hole with a hammer before Matty RH side) holds up and Pete (LH side) forms the head. Once the rivet is in, the temporary bolt in the adjacent hole is removed by Scott (LH foreground) and Tim and one of them quickly cleams the holes out with a drill. The whole procedure is then repeated, 886 times. In the background two more people are stripping down the cab side, as the next sub-assembly to be tackled.

Incoming! You do have to keep a few pairs of gloves on rotation when you are going for it.

Previous blog postings (16th February 2022, 14th January 2023, 24th May 2023) have commented on the extent to which parts of the original bonnet can be/ have been recovered. This is presented graphically in the two views below.

As an aside, the right hand cab sheet has been replaced as it had a large, square opening in it, which clearly had, at one time been fitted with a door. A recent perusal of the KS drawing list has highlighted a number of modifications made in 1929 prior to the locomotive being delivered to the Castlederg & Victoria Bridge Tramway. These include ‘side door to cab for starting engine’, sandboxes on platform’, ‘silencer central on top of casing’ and ‘oil cup for layshaft’. How much we regret changing those features back to the early configuration when we get the beast to run is something we can look forward to in the future.

Completing the riveting is not the end of the bodywork, there are still some matters of detail to address. These catches secure the hatches:

One curtailed catch has survived

Chris Barry has manufactured three new ones. One is shown here with the original.

New clips have also been made (original and new in the view below)

Just like the drawing and ready for fitting

The door latches are also a work in progress. These have been turned, and then had the square to locate the catch milled on, before being threaded.

A neat little jig has been made to form the bend

While they still need trimming to length (and there are a few more rivets to bang in) they form a pleasing detail.

As always, it is not just the external appearance tha has been addressed, the latches are off the Kerr Stuart drawings.

A couple of other critical details are the lamp brackets, front and rear. These are standard gaue brackets of unknown provenance which have been subject to a heavy makeover to re-fashion them into Kerr Stuart ones.

A lot of Ebay searches have gone into sourcing the correct pattern headlamps and they did not look like the photo below prior to a visit to the Rob Bishop lamp hospital.

There is still a new cab roof to make and some handles for the top hatch but we are pretty well close to being done with the body.