Before we pick up on the main focus of recent work, the last blog entry illustrated the patterns for the spectacle hinges and catches. These are the castings, ready for machining.

From a project perspective, the engine side of things has gone a bit south; to Salisbury to be precise and it yet to return. It is a little bit frustrating, but we’re not short of jobs. A trip to Minffordd saw this eclectic pile of tat extracted from the Maenofferen shed. After a sort-through, all of the material likely to be re-used was transferred to another wagon and taken to Boston Lodge.

Thirty minutes of fun to work out what is in this waggon and what we left behind

Obviously the big bit is the bonnet, enjoying a trip out ‘on the forks’

A pleasingly large amount of this is recoverable

Not the easiest thing to store in the Blacksmiths shop, so Rick & Matty dismantled it into its component parts. This view shows the construction formed of angle frames and steel sheet, with a lap strip connecting the upper and lower body panels. This will make a nice break between the new and old construction when we rivet it all back together.

It’s good to say that the flat packed body did not hang around in store for too long; it is seen here on the back of the Boston Lodge pick up at point of dispatch to the grit blasters in Nefyn.

In addition to the recoverable body panels the second pallet load includes the brake handle for the transmission brake, the clutch pedal and the frame to carry the fuel tank. The two sand pots have also gone for the grit blast treatment.

The fuel tank itself did not make the cut for restoration, for reasons that are all too obvious in this view. The fresh gas-cut hole is to aid recovery of the filler cap.

The cast iron filler cap is quite a beast which we will of course be re-using.

Back to the tank itself, this displays some interesting remnants of it’s past. The two short angle brackets on the front face originally secured an auxiliary paraffin tank. Paraffin was used as a more combustible fuel to help start the engine. It you look carefully it can be seen that the right handle angle (in this view) fixed to the tank is marginally longer that its’ left hand mate. Historically this angle was longer still and carried a teak plinth on which the paraffin tank was mounted. Interestingly the fuel tank is a welded construction, which begs the question why did they rivet the angle brackets to it?

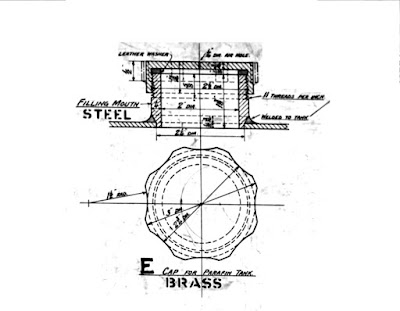

This drawing extract shows the paraffin tank in detail. There are also front elevation and plan views.

One of the joys of this project is of course the wealth of information available to inform the restoration. This is the detail for the filler cap to the paraffin tank. There is no mention of it being cast so Dave Linton has been dispatched with a suitable bit of brass bar to machine one up